MIL-PRF-24236D

3.25 Salt spray (corrosion). When switches are tested as specified in 4.6.20, switches shall show no evidence of

destructive corrosion. After the test, any mounting hardware (if applicable) shall be readily removable. NOTE:

Destructive corrosion shall be construed as being any type of corrosion which in any way interferes with the

mechanical or electrical performance, or in the case of plated metals, corrosion which has passed through the plating

and attacked the base metal.

3.26 Sand and dust (when specified, see 3.1). When switches are tested as specified in 4.6.21, the subsequent

operating characteristics shall be as specified (see 3.1), and they shall be mechanically and electrically operative at

the conclusion of the test.

3.27 Explosion (when specified, see 3.1). When switches are tested as specified in 4.6.22, there shall be no

explosion within the test chamber, whether or not explosion occurs within the switch, and the switches shall be

electrically and mechanically operative after the test.

3.28 Marking. Switches shall be marked in accordance with MIL-STD-1285, with the military part number or the

manufacturer's part number when specified (see 6.2.2), date code, and the manufacturer's trademark or cage code.

For polarized switches, the plus terminal shall be marked with a + sign.

3.28.1 Part or Identifying Number (PIN). The term Part or Identifying Number (PIN) is equivalent to the term part

number which was previously used in this specification. The performance PIN (when applicable) shall consist of the

'M' prefix followed by the applicable specification sheet number, a dash (-), and one of the following (see 3.1):

a. Sequentially assigned number (i.e., -001, -01) - Examples: M24236/1-001; M24236/14-01.

b. Letter codes assigned to indicate applicable design features (i.e., configuration, contact action, high

operating temperature, low operating temperature, probe length, etc.)

Examples: M24236/1-AGFEH; M24236/11-AACD; M24236/13-AHC; M24236/24-AGFEH.

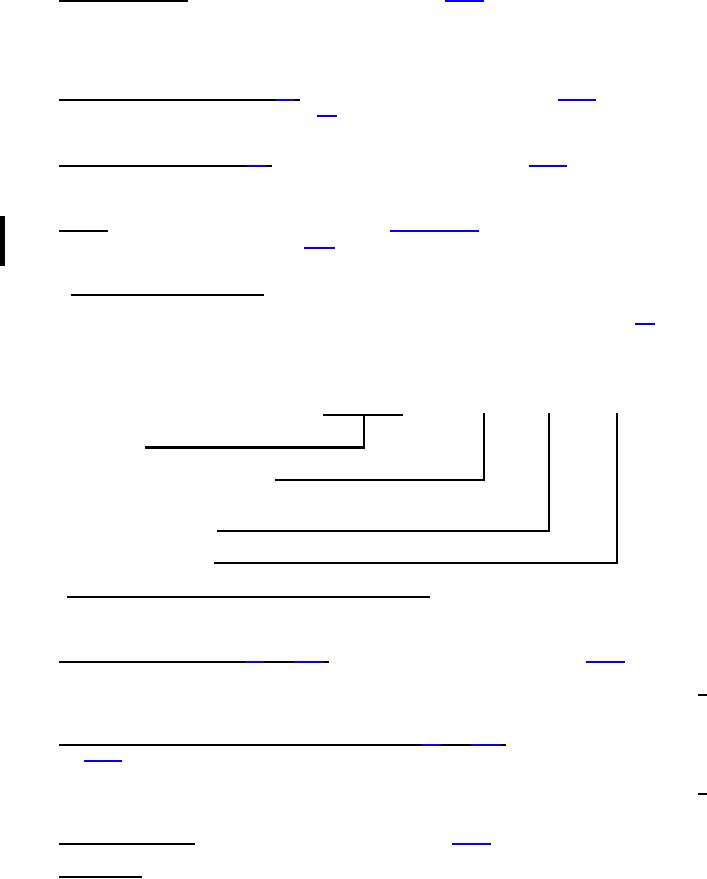

A

GF

EH

M24236/24 -

`M' prefix and specification

sheet number

Configuration (see figure or drawing

in specification sheet

High - temperature setting

Low - temperature setting

3.29 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or environmentally

preferable materials should be used to the maximum extent possible provided that the material meets or exceeds the

operational and maintenance requirements, and promotes economically advantageous life cycle costs.

3.30 Low level (when specified, see 3.1 and 6.2.2). When switches are tested as specified in 4.6.23, there shall be

no failures. A failure shall be a contact resistance exceeding 100 milliohms either during or after the test. The

allowable temperature tolerance during and after testing shall be the initial temperature tolerance and an additional +5

degrees F.

3.31 Minimum current (intermediate current) (when specified, see 3.1 and 6.2.2). When switches are tested as

specified in 4.6.24, there shall be no failures. A failure is defined as a cycle of operation during which any switch

circuit under test fails to close or open in proper sequence as detected by the relay and monitoring device. The

allowable temperature tolerance during and after testing shall be the initial temperature tolerance and an additional +5

degrees F.

3.32 Resistance to solvents. When switches are tested as specified in 4.6.25, the markings shall be legible.

3.33 Workmanship. Switches shall be processed in such a manner as to be uniform in quality and shall be free from

cracked or displaced parts, sharp edges, burrs, and other defects which will affect life, serviceability, or appearance.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business