MIL-PRF-24236D

4.4.5 Retention of qualification. Every 12 months, the manufacturer shall verify the retention of qualification to the

qualifying activity. Retention is based on meeting the following requirements:

a.

The manufacturer has not modified the design of the item.

b.

The specification requirements for the item have not been amended so far as to affect the character of

the item.

c.

Lot rejection for group A inspection does not exceed the group A sampling plan.

d.

The requirements for group B inspection are met every 36 months.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A inspection.

4.5.1.1 Inspection lot. An inspection lot shall consist of all switches of the same type produced under essentially

the same conditions, and offered for inspection at one time.

4.5.1.2 Group A inspection. Group A inspection shall consist of the examinations and tests specified in table II, in

the order shown.

4.5.1.2.1 Sampling plan. Statistical sampling and inspection shall be in accordance with table III. Separate,

randomly selected groups of samples are required for subgroups 1 and 3. For acceptance there shall be zero

occurrences of defects.

4.5.1.2.1.1 Subgroup 1. A sample of parts shall be randomly selected in accordance with table III

4.5.1.2.1.2 Subgroup 2. The lot shall be 100 percent inspected.

4.5.1.2.1.3 Subgroup 3. A sample of parts shall be randomly selected in accordance with table III.

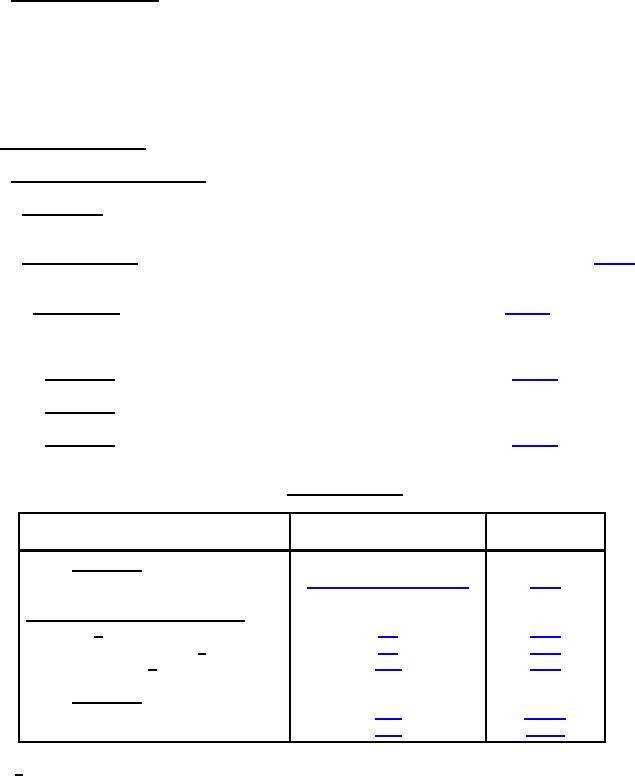

TABLE II. Group A inspection.

Method

Examination or test

Requirement paragraph

paragraph

Subgroup 1

Visual and mechanical examination

Subgroup 2 (100 percent inspection)

Calibration 1/

Creepage (when applicable) 1/

Seal (as applicable) 1/

Subgroup 3

Dielectric withstanding voltage

Contact resistance

1/ In process inspection may be used to satisfy these requirements.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business