MIL-PRF-24236D

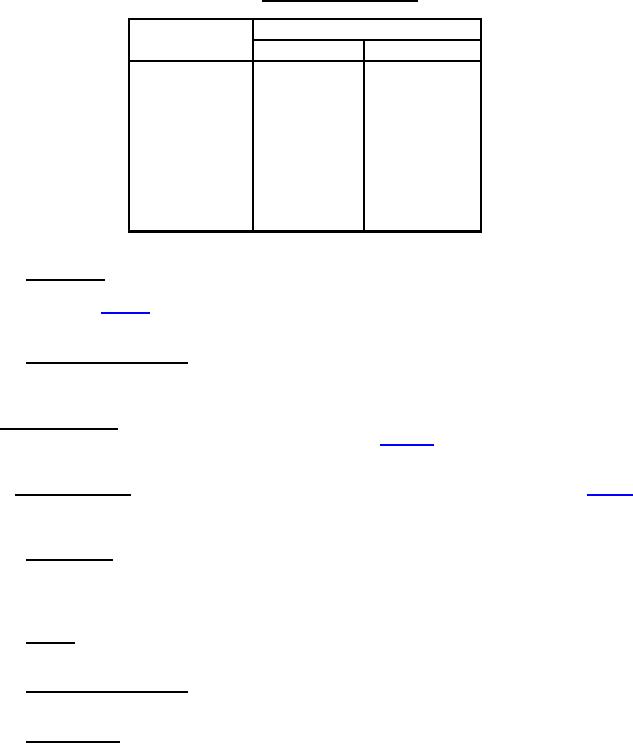

TABLE III. Zero defect sampling plan.

Number of switches to be tested

Lot size

Subgroup 1

Subgroup 3

All

5

1 - 15

20

5

16 - 50

20

7

51 - 90

20

11

91 - 150

20

13

151 - 280

47

16

281 - 500

47

19

501 - 1,200

53

23

1,201 - 3,200

68

29

3,201 - 10,000

77

35

10,001 - 35,000

4.5.1.2.2 Rejected lots. If an inspection lot is rejected, the lot shall be 100 percent inspected for the defects noted.

The contractor may correct the defects or remove the defective units from the lot. The lot shall then be sampled

again in accordance with table III. For acceptance, there shall be zero occurrences of defects. Such lots shall be

separate from new lots and shall be clearly identified as reinspected lots.

4.5.1.2.3 Disposition of sample units. Sample units which have passed all the group A inspection may be delivered

on the contract or purchase order, if the lot is accepted and the sample units are still within specified electrical

tolerances.

4.5.2 Periodic inspection. Periodic inspection shall consist of group B, except where the results of these

inspections show noncompliance with the applicable requirements (see 4.5.2.1.4), delivery of products which have

passed group A shall not be delayed pending the results of this qualification verification inspection.

4.5.2.1 Group B inspection. Group B inspection shall consist of the examinations and tests specified in table IV, in

the order shown. Group B inspection shall be made on sample units selected from inspection lots which have passed

the group A inspection.

4.5.2.1.1 Sampling plan. Six sample units shall be selected for each type of switch produced, within 36 months

after the date of notification of qualification and within each subsequent 36-month period. A supplier's normal quality

control tests, production tests, environmental tests, and so forth, may be used to fulfill all or part of group B

inspection; however, all of the group B inspection shall be completed as specified.

4.5.2.1.2 Failures. If one or more sample units fail to pass group B inspection, the sample shall be considered to

have failed.

4.5.2.1.3 Disposition of sample units. Sample units which have been subjected to group B inspection shall not be

delivered on the contract or purchase order.

4.5.2.1.4 Noncompliance. If a sample fails to pass group B inspection, the supplier shall take corrective action on

the materials or processes, or both, as warranted, and on all units of product which can be corrected and which were

manufactured under essentially the same conditions with essentially the same materials, processes, and so forth, and

which are considered subject to the same failures. Acceptance of the product shall be discontinued until corrective

action, acceptable to the Government, has been taken. After the corrective action has been taken, group B

inspection shall be repeated on additional sample units (all inspection, or the inspection which the original sample

failed, at the option of the Government). Group A inspection may be reinstituted, however, final acceptance shall be

withheld until the group B reinspection has shown that the corrective action was successful. In the event of failure

after reinspection, information concerning the failure and the corrective action taken shall be furnished to the

cognizant inspection activity and the qualifying activity.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business