MIL-PRF-24236D

6.3 Qualification. With respect to products requiring qualification, awards will be made only for products which are,

at the time of award of contract, qualified for inclusion in Qualified Products List QPL No. 24236 whether or not such

products have actually been so listed by that date. The attention of the contractors is called to these requirements,

and manufacturers are urged to arrange to have the products that they propose to offer to the Federal Government

tested for qualification in order that they may be eligible to be awarded contracts or orders for the products covered by

this specification. Information pertaining to qualification of products may be obtained from vqp.chief@dla.mil or

Defense Supply Center, Columbus, DSCC-VQP, 3990 East Broad Street, Columbus, OH 43216-5000.

6.4 Intermetallic contact. The finishing of metallic areas to be placed in intimate contact by assembly presents a

special problem, since intermetallic contact of dissimilar metals results in electrolytic couples which promote corrosion

through galvanic action. To provide the required corrosion protection, intermetallic couples should be restricted to

those permitted by MIL-HDBK-889.

6.4.1 Tin whisker growth. The use of alloys with tin content greater than 97 percent, by mass, may exhibit tin

whisker growth problems after manufacture. Tin whiskers may occur anytime from a day to years after manufacture

and can develop under typical operating conditions, on products that use such materials. Conformal coatings applied

over top of a whisker-prone surface will not prevent the formation of tin whiskers. Alloys of 3 percent lead, by mass,

have shown to inhibit the growth of tin whiskers. For additional information on this matter, refer to ASTM-B545

(Standard Specification for Electrodeposited Coatings of Tin).

6.5 Plastics. Type SDGF in accordance with ASTM 5948 is an acceptable flame retardant material.

6.6 Part or Identifying Number (PIN). This specification requires a PIN that is as described in the appropriate

reference to associated documents (see 3.1).

6.7 Subject term (key word) listing.

Bimetallic

Flame response

Hermetically sealed

Overheat detector

Temperature protection

Thermostatic

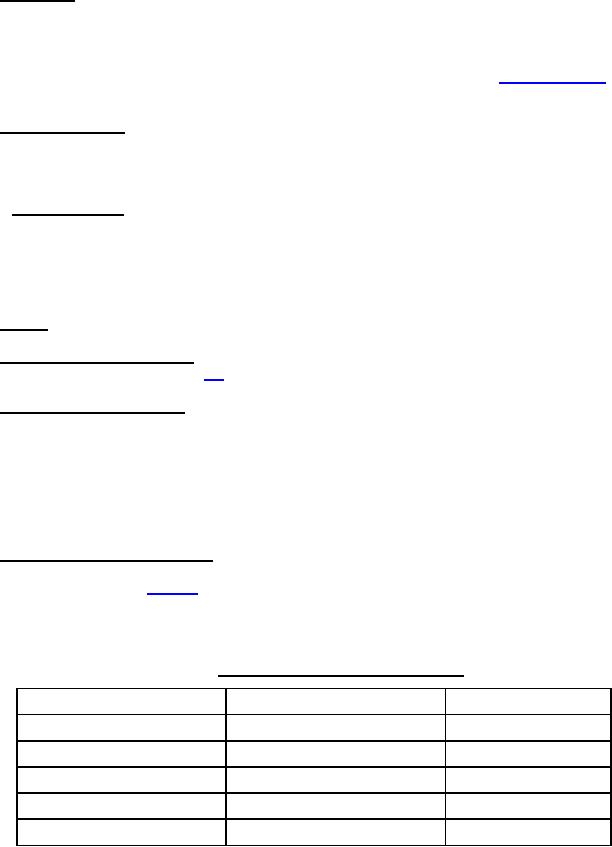

6.8 Environmentally preferable material. Environmentally preferable materials should be used to the maximum extent

possible that the material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle costs. Table VI lists the Environmental Protection Agency (EPA) top seventeen hazardous

materials targeted for major usage reduction. If any of these hazardous materials are required, it is recommended that it

be used only when other materials cannot meet performance requirements.

Table VI. EPA top seventeen hazardous materials.

Benzene

Dichloromethane

Tetrachloroethylene

Cadmium and Compounds

Lead and Compounds

Toluene

Carbon Tetrachoride

Mercury and Compounds

1,1,1 - Trichloroethane

Chloroform

Methyl Ethyle Ketone

Trichloroethyene

Chromium and Compounds

Methyl Isobutyl Ketone

Xylenes

Cyanide and Compounds

Nickel and Compounds

21

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business