MIL-DTL-24317B

4.8.9.2 Screw terminals. Switches with screw terminals shall be tested in accordance with 4.8.9.2.1

and 4.8.9.2.2.

4.8.9.2.1 Pull. Screw terminals shall be subjected to a pull of the applicable static force specified in

table IX in a direction along the axis of the terminal screw, in a direction perpendicular to the axis of the

terminal screw, and in the direction most likely to cause failure. No one terminal shall be tested in more

than one direction. The force shall be applied for one minute. After the test, switches shall be examined

for any damage and breakage, loosening, and rotation of terminals.

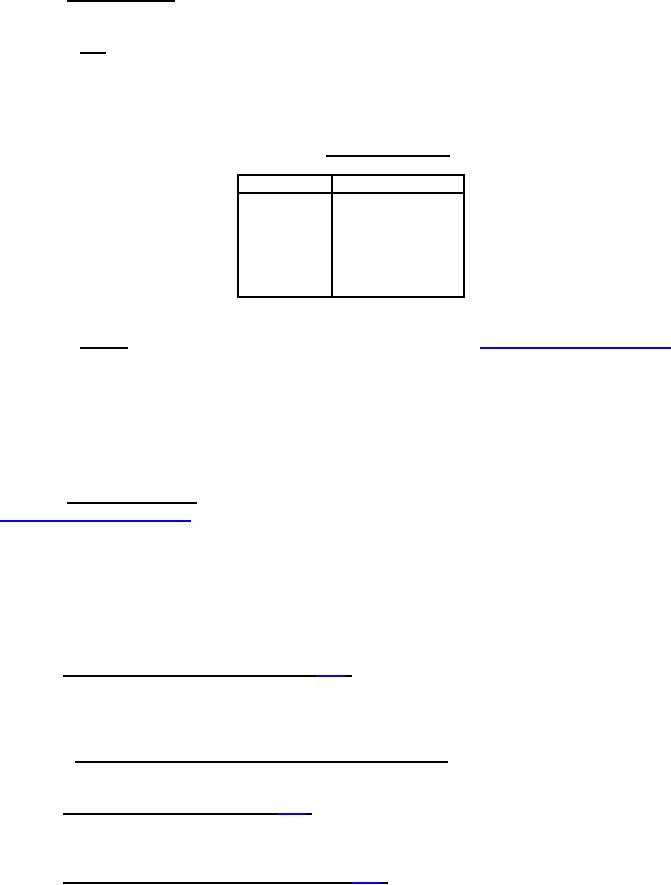

TABLE IX. Static force values.

Thread size

Force in pounds

4-40

5

6-32

30

8-32

35

10-32

40

10-24

40

1/4-28

50

4.8.9.2.2 Torque. Screw terminals shall be tested in accordance with method 211 of MIL-STD-202.

The following detail and exception shall apply:

(a) Test-condition letter E, except that for thread sizes 10-24, the torque shall be 24.0 pound-

inches.

(b) Direction of torque In the direction of the screw threads.

After the test, switches shall be examined for any damage and breakage, loosening and rotation of

terminals.

4.8.9.3 Wire-lead terminals. Switches with wire-lead terminals shall be tested in accordance with

method 211 of MIL-STD-202. The following details and exceptions shall apply:

(a) Test-condition letter A.

(b) Applied force 15 pounds.

(c) Direction of applied force In any direction, including the one most likely to cause failure.

(d) Duration of applied force One minute.

After the test, the switches shall be examined for any damage and breakage, loosening, and rotation of

terminals.

4.8.10 Lamp retention (when applicable, see 3.13). A lamp retention adapter in accordance with figure

1 shall be inserted (to complete lens engagement) and withdrawn five times. With the adapter installed in

the applicable lens, and the lens held so that the base on the adapter points directly downward, the unit

shall remain captive to the lens.

4.8.10.1 Insertion, withdrawal and removal force (snap-in lenses). Snap-in lenses shall be subjected to

an insertion, withdrawal and removal test to determine conformance with 3.4.7.1.

4.8.11 Torque strength of plunger (see 3.14). With the switches mounted by normal means, a torque

of 5 inch-pounds shall be applied to the plunger in a plane perpendicular to the centerline of the plunger

for a period of 1 minute.

4.8.12 Strength of actuator and actuator stop (see 3.15). With the switch mounted by normal means, a

static load of 25 pounds, unless otherwise specified (see 3.1), shall gradually be applied in line with the

actuator for a period of 1 minute.

17

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business