MIL-DTL-24317B

3.25 Marking. Switches shall be marked in accordance with MIL-STD-130, with the following

information:

(a) Manufacturer's name, trademark, or code symbol (the code symbol shall be in accordance with

(b) Military part number, type designation or manufacturer's part number when not covered by a

specification sheet.

(c) Date code in accordance with MIL-STD-1285.

3.26 Workmanship. Switches shall be processed in such a manner as to be uniform in quality and

shall be free from defects that will affect life, serviceability, or appearance.

3.26.1 Lens (when applicable, see 3.1). Lens shall be free from open surface bubbles or internal

bubbles which may be observed with lamps energized.

4. VERIFICATION

4.1 Classification of inspection. The examination and testing of switches shall be classified as follows:

(a) Component-materials inspection (see 4.3).

(b) Qualification inspection (see 4.5).

(c) Preproduction inspection (see 4.6).

(d) Quality conformance inspection (see 4.7).

(1) Inspection of product for delivery (see 4.7.1).

(2) Inspection of preparation for delivery (see 4.7.2).

4.2 Test equipment and inspection facilities. Test and measuring equipment and inspection facilities of

sufficient accuracy, quality, and quantity to permit performance of the required inspection shall be

established and maintained by the contractor. The establishment and maintenance of a calibration

system to control the accuracy of the measuring and test equipment shall be in accordance with

ANSI/NCSL Z540.3, ISO 10012-1 or approved equivalent.

4.3 Component-materials inspection. Component-materials inspection shall consist of verification that

the component materials listed in table IV, used in fabricating the switches, are in accordance with the

applicable referenced specifications or requirements prior to such fabrication.

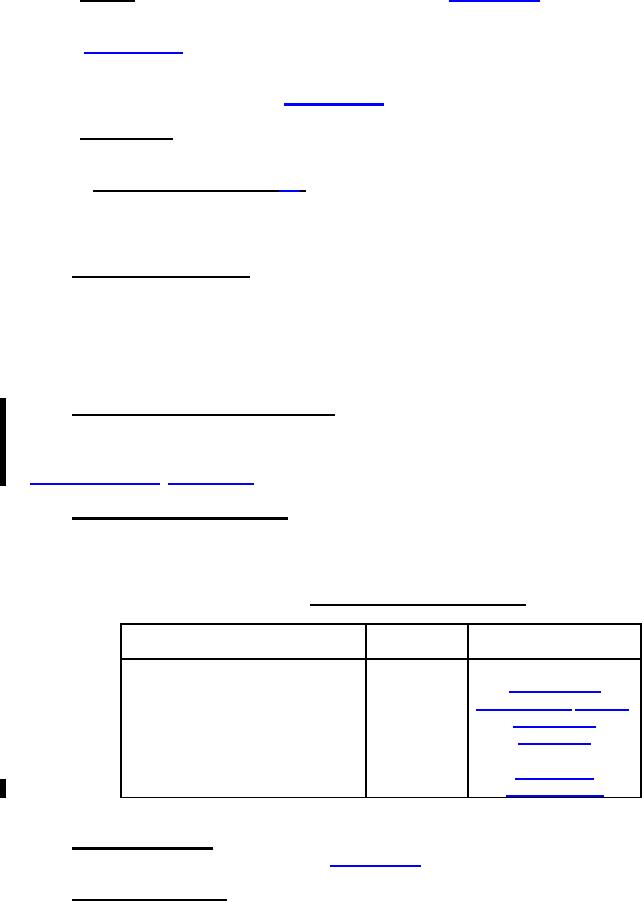

TABLE IV. Component-materials inspection.

Applicable specification

Requirement

Component material

paragraph

or requirement

Plastic material:

Thermosetting

Thermoplastics

Rubber

Finish:

Anodized aluminum

Chemical treatment for aluminum

4.4 Inspection conditions. Unless otherwise specified herein, all inspections shall be made in

accordance with the general requirements of MIL-STD-202.

4.5 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable to

the Government (see 6.3) on sample units produced with equipment and procedures normally used in

production.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business