MIL-PRF-22885H

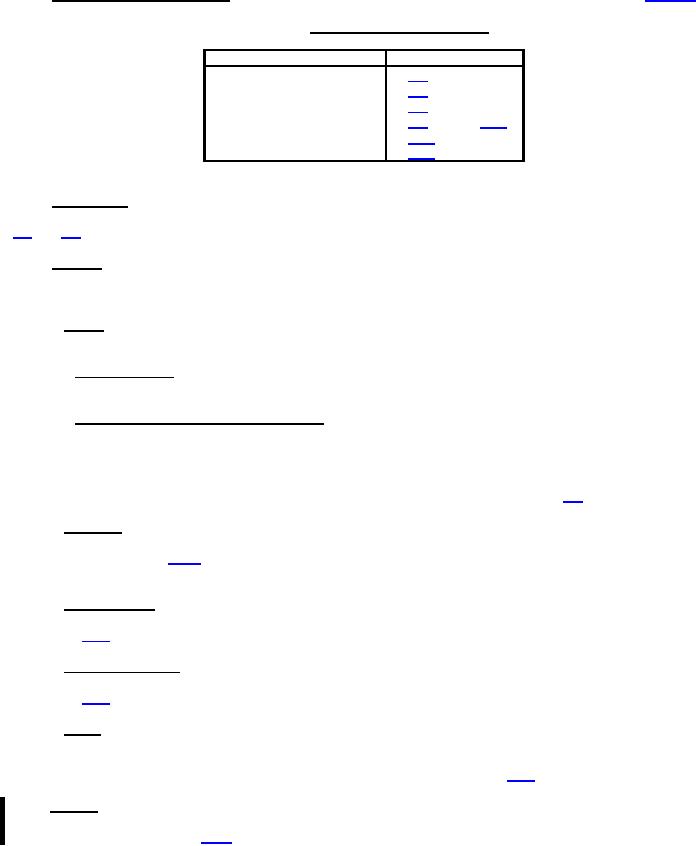

3.3 Classification of requirements. The requirements for the switches are classified in accordance with table VII.

TABLE VII. Classification of requirements.

Requirement

Paragraph

Qualification

Material

Interface and dimensions

Performance

Marking

Workmanship

3.4 Qualification. Category I switches furnished under this specification shall be products that are manufactured

by a manufacturer authorized by the qualifying activity for listing on the applicable QPL before contract award (see

3.5 Material. Material shall be as specified herein. However, when a definite material is not specified, a material

shall be used which will enable the switches to meet the performance requirements of this specification. Acceptance

or approval of any constituent material shall not be construed as a guaranty of the acceptance of the finished product.

3.5.1 Metals. All metal parts, other than current-carrying parts, shall be of corrosion-resistant material or shall be

suitably protected to resist corrosion.

3.5.1.1 Ferrous material. Ferrous material shall not be used for current-carrying parts except for feed-through

terminals in headers.

3.5.1.2 Dissimilar metals and compatible couples. When dissimilar metals are used in intimate contact with each

other, protection against electrolysis and corrosion shall be provided. The use of dissimilar metals in contact, which

tend toward active electrolytic corrosion (particularly brass, copper, or steel used in contact with aluminum or

aluminum alloy) is not acceptable. However, metal plating or metal spraying of dissimilar base metals to provide

similar or suitable abutting surfaces is permitted. The use of dissimilar metals separated by a suitable insulating

material is also permitted. For additional information and guidance on dissimilar metals see 6.8.

3.5.2 Insulation. Materials for insulation shall be used which will enable the switch to meet the performance

requirements of this specification. Plastic materials shall be fungus inert and shall meet flammability requirements of

94V-0 in accordance with UL94. Additional information and guidance on ceramic and thermoplastic material is

provided in 6.9.

3.5.3 Silicone rubber. Silicone rubber parts, when used, shall be selected to enable the switch to meet

performance requirements of this specification. Additional information and guidance on rubber material is

provided in 6.10.

3.5.4 Potting compounds. Potting compounds, when used, shall be selected to enable the switch to meet

performance requirements of this specification. Additional information and guidance on potting compounds is

provided in 6.11.

3.5.5 Finish. Aluminum parts, when used, shall be anodized or chemically treated to enable the switch to meet the

performance requirements of this specification. Bezels, mounting flanges, barriers, mounting bushings and

associated mounting hardware that are designed to be exposed at the front of the panel after assembly shall have a

black lusterless finish. Additional information and guidance on finish is provided in 6.12.

3.5.6 Pure tin. The use of pure tin, as an underplate or final finish, is prohibited both internally and externally. Tin

content of switch components and solder shall not exceed 97 percent, by mass. Tin shall be alloyed with a minimum

of 3 percent lead, by mass (see 6.16)

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business