MIL-PRF-22885H

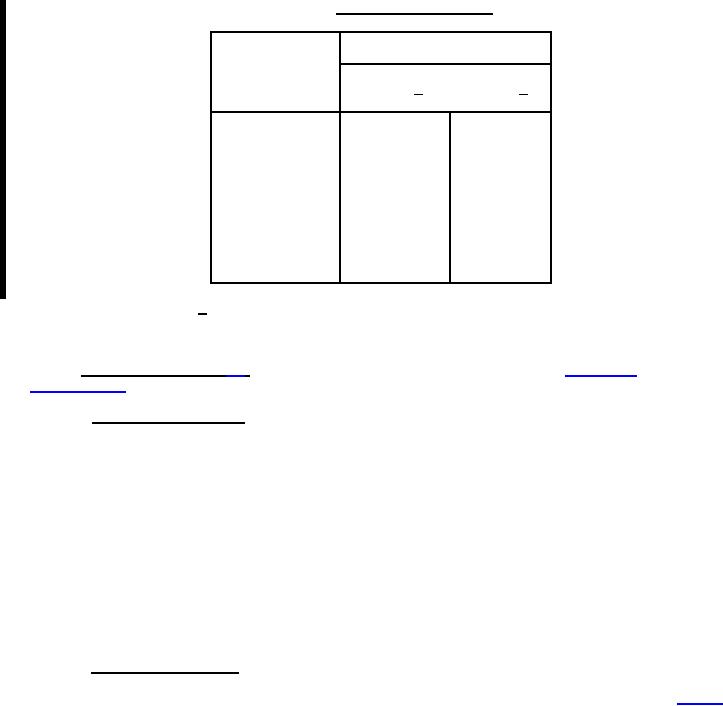

TABLE XI. Zero defect sampling plan.

Number of switches

Lot size

to be tested

Subgroup 2

Subgroup 1

(major) 1/

(minor) 1/

1-

8

All

All

9-

12

All

5

13 -

50

13

5

51 -

90

13

7

91 -

150

13

11

151 -

280

20

13

281 -

500

29

16

501 - 1,200

34

19

1,201 - 3,200

42

23

3,201 - 10,000

50

29

10,001 - 35,000

60

35

1/

Major and minor defects are defined in section 6.

Inspection for minor defects is applicable to visual

and mechanical examination only.

4.7.4.1 Switch contact resistance. The following details shall apply:

a.

Measurements shall be made between the terminals of the contacts of the same pole forming a switching

circuit. Three measurements shall be made on each pair of switch contacts. The switch contacts shall be

operated once between each measurement.

Test current: 0.1 ampere ±5 percent. After electrical endurance, use the electrical parameters of the

b.

electrical endurance test load.

Open-circuit test voltage: 6 volts direct current (V dc) ±1 V dc. After electrical endurance, use the electrical

c.

parameters of the electrical endurance test load.

d.

Number of test actuations: Three.

e.

Number of measurements per actuation: One measurement.

4.7.4.2 Lamp contact resistance. The following details shall apply:

Preparation for test: Lamp circuit continuity shall be established using the applicable test plug (see figure 2).

a.

Test current: 0.1 ampere ± 5 percent.

b.

Test voltage: 6 V dc ±1 V dc.

c.

d.

Number of test plug insertions: Three.

e.

Number of measurements per insertion: One measurement.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business