MIL-PRF-22710H

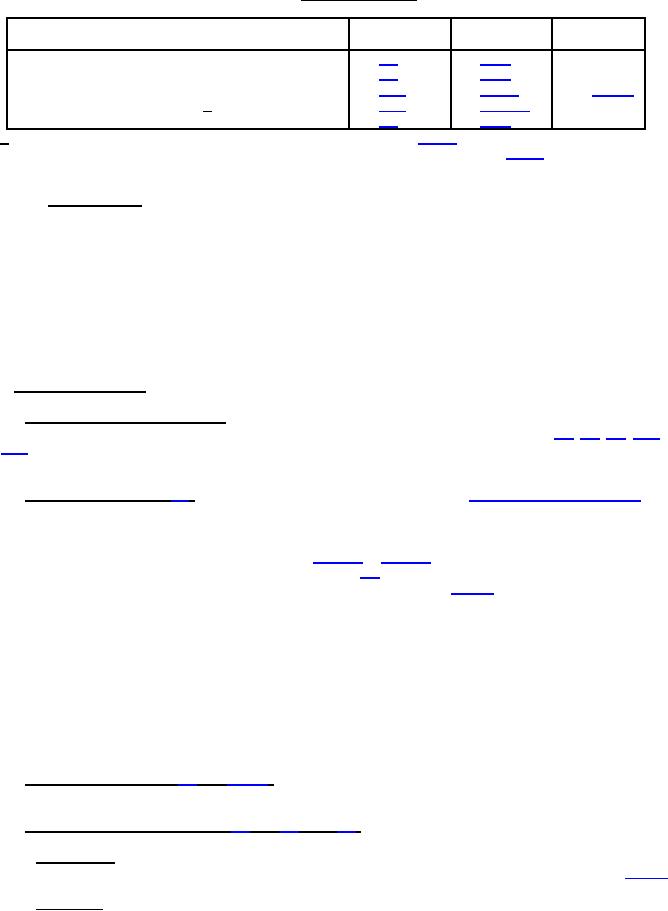

TABLE IX. Group B inspection.

Requirement

Test method

Sampling

Inspection

paragraph

requirement

plan

Rotational torque or operational force (as applicable)

Stops (when applicable)

See 4.4.3.1

Seal (when applicable)

Dielectric withstanding voltage 1/

Contact resistance

1/ For sealed switches, use the dielectric withstanding voltage test of 4.5.14 at atmospheric pressure (sea

level) only. For unsealed switches, use the dielectric withstanding voltage test of 4.5.15.

4.4.4.1.4 Noncompliance. If a sample fails to pass group C inspection, the contractor shall notify the qualifying

activity and the cognizant inspection activity of such failure and take corrective action on the materials or processes,

or both, as warranted, and on all units of product which can be corrected and which were manufactured under

essentially the same conditions, with essentially the same materials, processes, etc., and which are considered

subject to the same failure. Acceptance and shipment of the product shall be discontinued until corrective action,

acceptable to the qualifying activity, has been taken. After the corrective action has been taken, group C inspection

shall be repeated on additional sample units (all inspection, or the inspection which the original sample failed, at the

option of the qualifying activity). Group A and group B inspection may be reinstituted; however, final acceptance and

shipment shall be withheld until the group C inspection has shown that the corrective action was successful. In the

event of failure after reinspection, information concerning the failure shall be furnished to the cognizant inspection

activity and the qualifying activity.

4.5 Methods of inspection.

4.5.1 Visual and mechanical inspection. Switches shall be inspected to verify that the material, interface and

dimensions, marking, and workmanship are in accordance with the applicable requirements (see 3.1, 3.3, 3.4, 3.28,

and 3.30). Only two of the sample units shall be inspected for compliance to interface and dimensions for

qualification.

4.5.2 Contact resistance (see 3.5). Switches shall be tested in accordance with method 307 of MIL-STD-202. The

following details and exceptions shall apply:

a. Method of connection: To two different pairs of mating contacts on each switch module or section. Where the

switch has undergone a life (rotational) test (see 4.5.22.1 or 4.5.22.2 as applicable), the contacts shall have

been subjected to the specified electrical test loads (see 3.1). At least one of the stationary contacts on each

section shall have been subjected to the terminal-strength pull test (see 4.5.8.1).

b. Test current: 100 milliamperes.

c. Maximum open-circuit test voltage: 2 volts.

d. Number of activations prior to measurement: One cycle.

e. Number of tests activations: One for each dial position in which the pair of contacts are mated.

f. Number of measurements per activation: One of each pair of mating contacts under test, except that a

minimum of four shall be made on each switch when possible.

4.5.3 Circuit configuration (see 3.6 and 3.4.7.2). Switches shall be tested to determine conformance to the

applicable diagram using suitable test circuits of an electrical design. The lamp circuit shall be tested electrically.

4.5.4.1 Indicator ring. The luminance of the illumination of the marking and the luminance of the background shall

be measured. The relationship between readings shall be in accordance with the applicable requirements of 3.4.7.1.

4.5.4.2 Luminance. A Photo Research photometric brightness meter or equivalent shall be used. At least three

readings (top-center-bottom) shall be taken on each of three characters spaced equally (or nearly so) around the dial.

The average of all of the readings shall be the brightness and must fall within the limits specified. In addition, no one

individual reading shall be more than 25 percent outside of the specified limits.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business