MIL-PRF-22710H

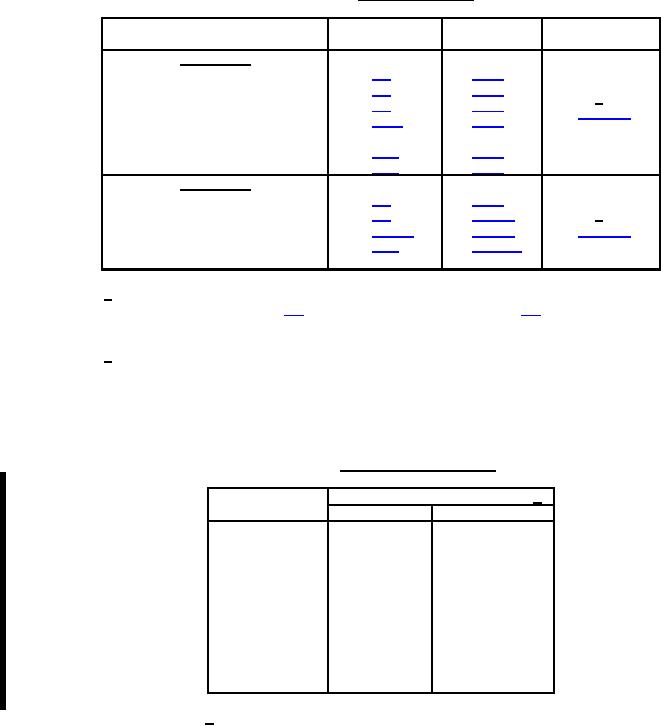

TABLE VII. Group A inspection.

Requirement

Test method

Sampling

Inspection

paragraph

paragraph

plan

Subgroup 1

Visual and mechanical inspection

Material

1/

Interface and dimensions

See 4.4.2.1.1

Lamp circuitry and illumination

(when applicable)

Marking

Workmanship

Subgroup 2

Circuit configuration

Luminance

2/

See 4.4.2.1.2

Color (when applicable)

EMI/RFI shielding (when specified

(see 3.1))

1/

At the option of the contractor, documented in-process inspection may be used to

provided that all of the contractor's in-process control data on these tests are made

available to the Government upon request.

2/

At the option of the contractor, incoming or in-process inspection by photometric

measurement of raw materials may be used to meet the color and luminance

requirements provided that they meet the acceptance criteria and all of the contractor's

in-process control data on these tests and are made available to the Government upon

request.

TABLE VIII. Zero defect sampling plan.

Number of switches to be tested 1/

Lot size

Subgroup 1

Subgroup 2

1-

4

All

All

5-

12

5

All

13 -

50

5

13

51 -

90

7

13

91 -

150

11

13

151 -

280

13

20

281 -

500

16

29

501 - 1,200

19

34

1,201 - 3,200

23

42

3,201 - 10,000

29

50

10,001 - 35,000

35

60

1/ If the sample size is greater than the lot size, the lot

shall be 100 percent inspected.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business