MIL-DTL-3950J

4.7.2.1.1 Sampling plan. The sampling plan and test procedures shall be as specified in the appendix

to this specification. The sample units shall be selected from current production. If switches are not in

current production, they may be selected from stock; however, all switches shall be date coded within 24

months of the required group B submittal date. When there has been no production of a particular type of

switch for a 3-year period, sample units shall be selected from the next production lot presented for

acceptance and for each subsequent 3-year period.

4.7.2.1.2 Noncompliance. If a sample fails to pass group B inspection, the supplier shall take

corrective action on the materials or processes, or both, as warranted, and on all units of product which

can be corrected and which were manufactured under essentially the same conditions, with essentially

the same materials, processes, etc., and which are considered subject to the same failure. Acceptance

of the product shall be discontinued until corrective action, acceptable to the preparing activity, has been

taken. After the corrective action has been taken, group B inspection shall be repeated on additional

sample units (all inspections, or the inspection which the original sample failed, at the option of the

preparing activity). Group A inspection may be reinstituted; however, final acceptance shall be withheld

until the group B reinspection has shown that the corrective action was successful.

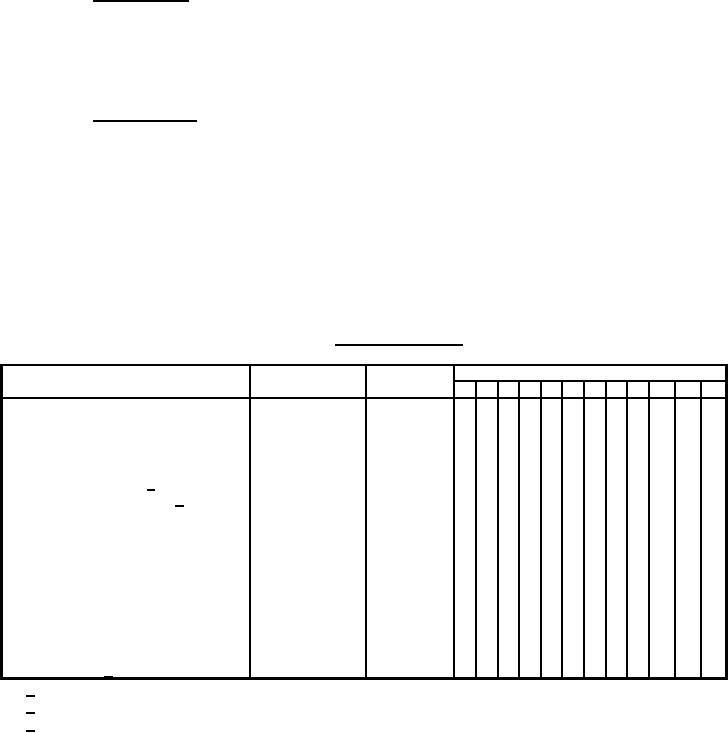

TABLE V. Group B inspection.

Specimen

Requirement

Test

Inspection

paragraph

paragraph

1

2

3

4

5678

9 10 11 12

Mechanical endurance..........................

x

x

Electrical overload, electrical

endurance, intermediate current,

low-level life, and temperature rise .....

Overload current .............................

x

x

x

x

Resistive load (ac) 1/......................

x

x

Inductive load (altitude) 2/ ..............

x

x

Life, low level ..................................

x

x

Temperature rise.............................

x

x

Contact voltage drop.............................

x

x

Shock....................................................

x

x

Salt spray (corrosion)............................

x

x

Solderability ..........................................

x

x

Dielectric withstanding voltage

(At atmospheric pressure) ..................

x

x

x

x

Examination of product .........................

x

x

x

x

x

x

x

x

x

x

x

x

Switching characteristics ......................

x

x

x

x

x

x

x

x

x

x

Switch sealing 3/.................................

x

x

x

x

x

x

x

x

x

x

1/ Test at 115 volts, 60 Hz, 71°C.

2/ Test at 28 V dc, 65,000 feet.

3/ Only the odd-numbered specimens shall be opened by the manufacturer.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business