MIL-DTL-3950J

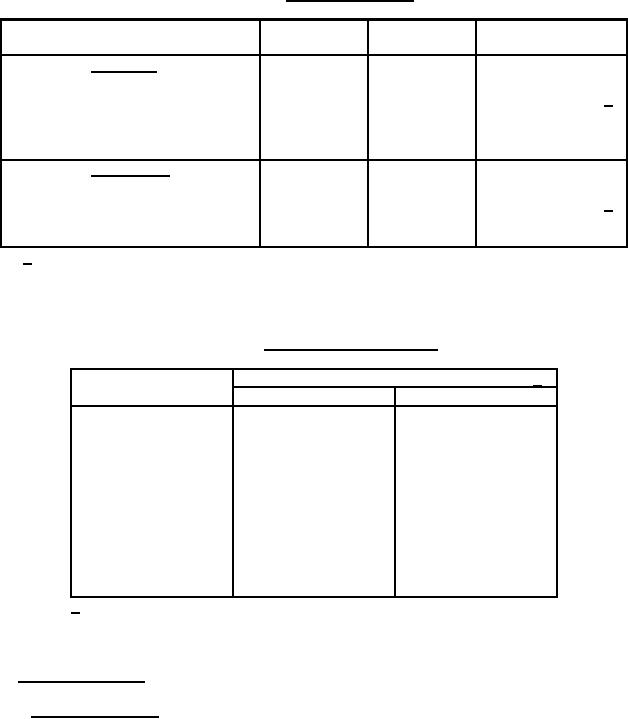

TABLE III. Group A inspection.

Requirement

Test method

Inspection

Sampling plan

paragraph

paragraph

Subgroup 1

Examination of product

Material

Interface and Physical dimensions

Marking

Workmanship

Subgroup 2

Switch sealing

4.8.19.1(b)

Switching characteristics

See 4.7.1.2.1.2 1/

Dielectric withstanding voltage

Contact voltage drop

1/ At the option of the contractor, documented in-process inspection may be used to

satisfy the requirements provided that all of the contractor's in-process control data

on these tests are made available to the Government upon request.

TABLE IV. Zero defect sampling plan.

Minimum number of switches to be tested 1/

Lot Size

Subgroup 1

Subgroup 2

1-

8

All

All

9-

15

5

All

16 -

50

5

13

51 -

90

7

13

91 -

150

11

13

151 -

280

13

20

281 -

500

16

29

501 - 1,200

19

34

1,201 - 3,200

23

42

3,201 - 10,000

29

50

10,000 - 35,000

35

60

1/ For lot sizes that are less than the required sample size, all switches

shall be tested.

4.7.2 Periodic inspection.

4.7.2.1 Group B inspection. Group B inspection shall be completed in accordance with table V, in the

order shown, within each 3-year period after initial qualification. When a manufacturer has switches

qualified under various MS standards or specification sheets, the qualifying activity may authorize group

B tests that do not require redundant testing on similar product features. Group B inspection shall be

performed on sample units that have been produced, using the same manufacturing facilities and

processes normally used in production and which have passed group A inspection. A manufacturer's

normal quality control tests, production tests, and environmental tests may be used to fulfill all or part of

group B inspection; however, all of group B inspection shall be completed as specified. Data used may

be accumulated within the previous 24 months.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business