MIL-DTL-28788C

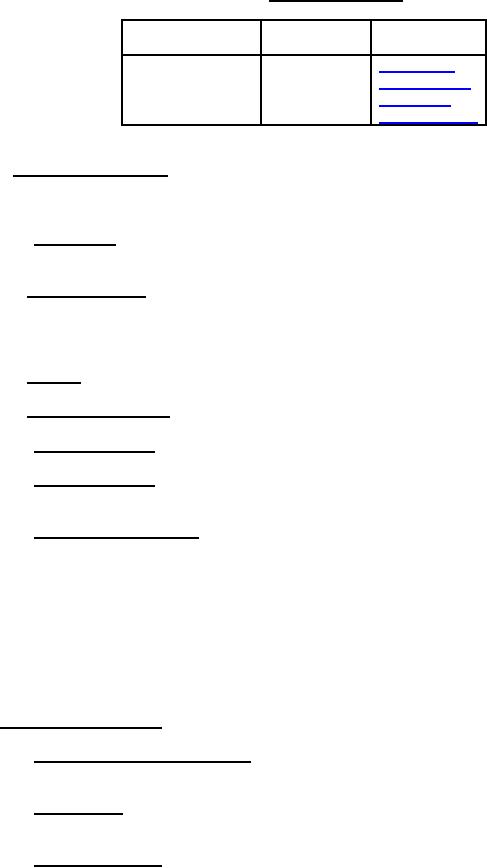

TABLE I. Materials inspection.

Requirement

Applicable

Material

Paragraph

Specification

Fungus resistance

Plastic

Rubber

Ceramic

4.5 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable

to the Government (see 6.2) on sample units produced with equipment and procedures normally used in

production.

4.5.1 Sample size. The number of switches to be subjected to qualification inspection shall be as

4.5.2 Inspection routine. The sample shall be subjected to the inspections specified in table II, in

the order shown. All sample units shall be subjected to the inspections of group I. The sample shall then

be divided as specified in table II for groups II through V inclusive, and subjected to the inspection for

their particular group.

4.5.3 Failures. One or more failures shall be cause for refusal to grant qualification approval.

4.5.4 Extent of qualification.

4.5.4.1 Single submission. Qualification shall be restricted to the switch submitted.

4.5.4.2 Group submission. The extent of qualification shall be in accordance with the applicable

specification sheet (see 3.1).

4.5.5 Retention of qualification. To retain qualification, the contractor shall submit a summary of

the results of the tests performed for inspection of product for delivery (group A), and a certification of

compliance at yearly intervals via the Government quality assurance representative. The summary of

group A shall indicate the number of inspection lots that passed and the number that failed (including the

number and type of failures) together with corrective action taken to correct failures. The certification of

compliance shall include verification that materials, processes, and quality control have not changed.

Failure to submit the group A summary and certification of compliance shall result in loss of qualification.

If the summary of the test results indicates nonconformance with the specification requirements, and

corrective action acceptable to the qualifying activity has not been taken, action may be taken to remove

the failing product from the qualified products list.

4.6 Conformance inspection.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A

inspection.

4.6.1.1 Inspection lot. An inspection lot shall consist of all switches of the same type, produced

under essentially the same conditions, and offered for inspection at one time.

4.6.1.2 Group A inspection. Group A inspection shall consist of the examinations and tests specified

in table III, in the order shown. Differential pressure, insulation resistance, and dielectric withstanding

voltage shall be within the limits specified. Actual values need not be recorded.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business