MIL-DTL-28788C

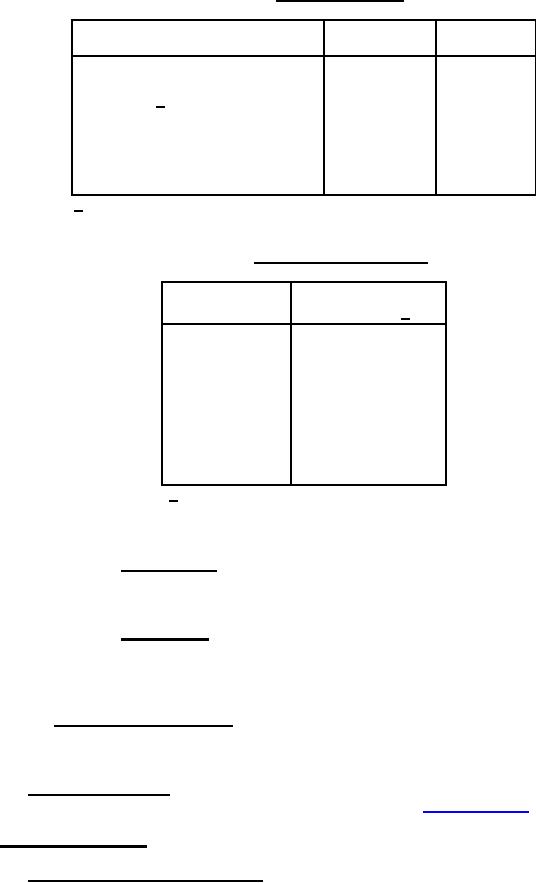

TABLE III. Group A inspection.

Requirement

Test method

Inspection

Paragraph

Paragraph

Calibration

Run-in (when specified)

Calibration 1/

Dielectric withstanding voltage

Insulation resistance

Seal (when specified)

1/ Applicable only when run-in is required.

TABLE IV. Zero defect sampling plan.

Number of switches

Lot size

to be tested1/

1

- 50

5

51

- 90

7

91

- 150

11

151

- 280

13

231

- 500

16

501

- 1,200

19

1,201

- 3,200

23

3,201

- 10,000

29

10,001

- 35,000

35

1/ For lot sizes that are less than required

sample size, all switches shall be tested.

4.6.1.2.1

Sampling plan. Statistical sampling shall be in accordance with table III and

table IV. A randomly selected group(s) of samples is required. For acceptance of the lot there shall be

zero occurrences of defects.

4.6.1.2.2

Rejected lots. If an inspection lot is rejected, the contractor may rework it to

correct the defects, or screen out the defective units, and resubmit for reinspection. Resubmitted lots

shall be inspected using tightened inspection. Such lots shall be separate from new lots, and shall be

clearly identified as reinspected lots.

4.6.1.2.3 Disposition of sample units. Sample units which have passed all the group A inspection

may be delivered on the contract, if the lot is accepted and the sample units are still within specified

electrical tolerances.

4.6.2 Packaging inspection. The sampling and inspection of the preservation-packaging, packing

and container marking shall be in accordance with the requirements of MIL-DTL-28786.

4.7 Methods of inspection.

4.7.1 Visual and mechanical examination. Switches shall be examined to determine that the

materials, design, construction, physical dimensions, marking, and workmanship are in accordance with

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business