MIL-DTL-15291G

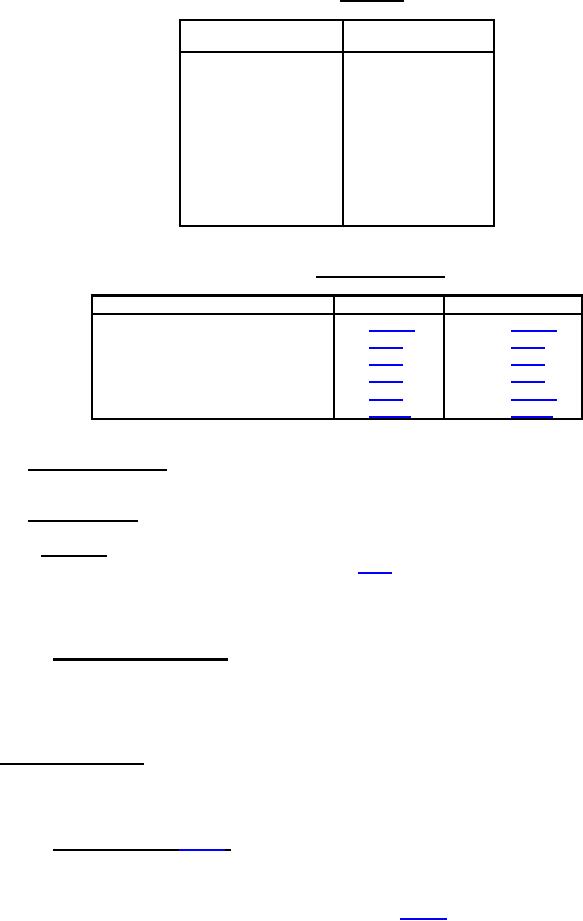

TABLE V. Sampling.

Minimum number of

Lot size

switches to be tested

1

to

50

All

51

to

90

All

91

to

150

90

151

to

280

125

281

to

500

125

501

to

1,200

125

1,201

to

3,200

125

3,201

to

10,000

192

10,001

to

35,000

294

35,001

to

150,000

294

TABLE VI. Group B inspection.

Inspection

Requirement

Test method

Stop strength

Dielectric withstanding voltage

Contact resistance

Temperature rise

Endurance, ac

Insulation resistance

4.6 General examination. Switches shall be examined to verify that the materials, design, construction,

physical dimensions, and marking are in accordance with this specification

4.7 Test procedures.

4.7.1 Operation. The operation test shall consist of the minimum number of electrical operations to

ascertain that the switching action is in accordance with 3.6.1. The switch shall be energized at any

convenient voltage and current within the switch rating. A suitable audible or visual device shall be used

to indicate the opening and closing of the circuits at each position and/or each deck for multideck

switches. Suitable measuring devices shall be used to determine whether transfer action is as specified.

4.7.1.1 Momentary position return. The switch shall be mounted by its normal mounting means. The

switch operating shaft shall be rotated 75 ± 5 degrees from an adjacent rest position toward a momentary

position and released. This test shall be made for each momentary position of the switch blades.

Normally closed circuits shall be tested for continuity and handle shaft displacement and float shall be

measured.

4.7.1.2 Stop strength. The switch shall be mounted by its normal mounting means. The switch shaft

shall be rotated to the clockwise and counterclockwise extremes and a torque in accordance with table

VII shall be applied to the switch shaft and maintained for 10 seconds. Switch contacts shall be

monitored for open or closed conditions in the stop positions.

4.7.1.3 Transfer time (see 3.6.1.3). The time between the opening of an initially closed contact and the

closing of the initially open contact shall be measured using an oscilloscope capable of measuring to 500

microseconds. The contacts being used for measurement shall be of the break before make style and

shall be 90 degrees a part. Three clockwise measurements and three counterclockwise measurements

shall be taken and the average transfer time shall comply with 3.6.1.3.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business