MIL-DTL-12285F

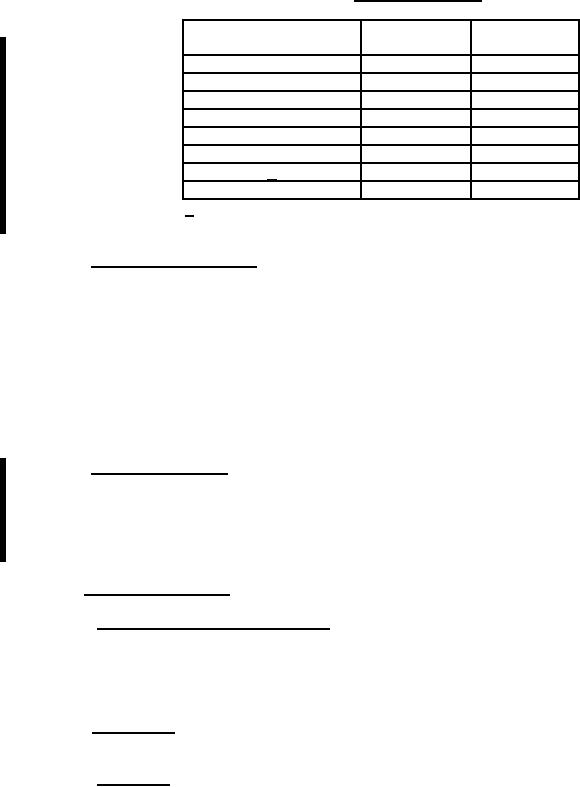

TABLE IV. Group B inspection.

Requirement

Test method

Inspection

paragraph

paragraph

High temperature

Waterproofness

Corrosion

Fungus

Shock

Vibration

Endurance 1/

Examination of product

1/ If the internal switch is a QPL 24236 switch, endurance

testing does not need to be completed.

4.6.3 Retention of qualification. To retain qualification, the supplier shall forward to the qualifying

activity via Government quality assurance representative at yearly intervals, summaries of group A

inspection for that period, along with group B test reports, when applicable. The summary of group A

inspections shall indicate as a minimum the number of inspection lots which have passed and the number

which failed (including the number and type of any part failures, the reason for failure, the corrective

action taken and how the lot was reexamined). The group B test report shall cover the actual tests

performed. If the results for group B tests indicate nonconformance with the specification requirements,

action shall be taken to remove the failing products from the qualified products list. Failure to submit the

summary shall result in loss of qualification for that product. In the event that no production occurred

during the reporting period, a report shall be submitted certifying that the company still has the

capabilities and facilities necessary to produce the item.

4.6.4 Group B suspension. At the request of the manufacturer group B testing may be suspended

with the qualifying activity's approval, if it can be demonstrated that these test have been performed 3

consecutive times with zero failures, If the design, material, construction, or processing is changed or if

there are any quality problems or failures, the qualifying activity may require resumption of the original

testing requirement. Regardless of reduction of tests, the manufacturer shall supply product capable of

passing the prescribed tests.

4.7 Methods of inspection.

determined by inspection of contractor records providing proof or certification that design, construction,

processing, and materials conform to requirements. Applicable records shall include drawings,

specifications, design data, receiving inspection records, processing and quality control standards, vendor

catalogs and certifications, industry standards, test reports, and rating data.

specified in table II.

4.7.3 Calibration. To determine conformance to 3.5.1, the sample shall be mounted as specified in

4.3 in such a position that the circulating oil-bath will cover it to the smaller end of the tapered thread.

The switch shall be connected through the indicator lamp to the voltage supply. The initial oil-bath

temperature shall be a minimum of 6ºC (10.8ºF) below the rated temperature of the switch. Oil bath

temperature shall be increased at a rate no greater than 0.58ºC (1ºF) per minute. The temperature at

which the switch contacts close the circuit shall be recorded.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business