MIL-DTL-12285F

4.5.3 Certification of material. When submitting samples for qualification, the manufacturer shall

submit certification that the materials used in his components are in accordance with the applicable

specification requirements, or shall state whether other materials are used. With the qualification test

report, the manufacturer shall submit a cross-reference list of the switch parts and the materials used to

fabricate those parts.

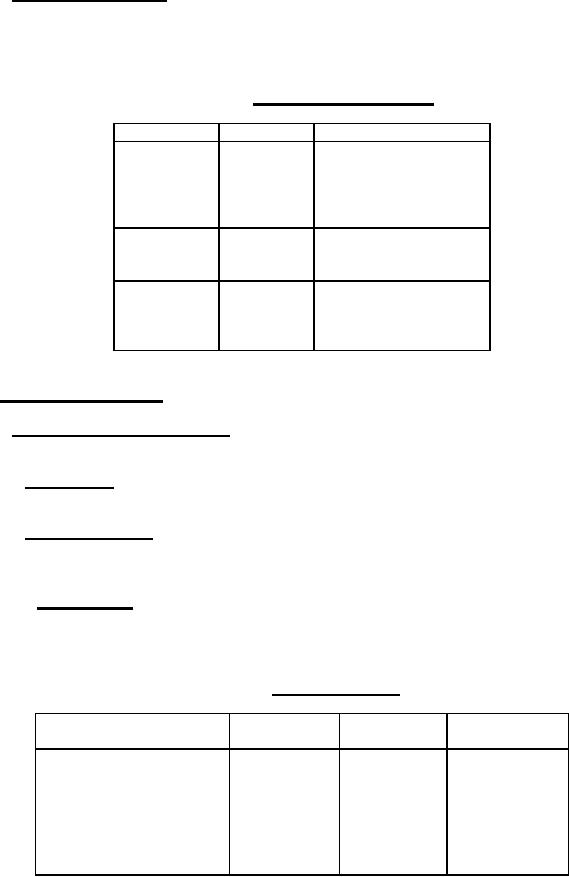

TABLE I. Qualification test sequence.

Sample No.

Paragraph

Test

Calibration

High temperature

1

Vibration

Calibration

Fungus

Calibration

2

Endurance

Corrosion

Calibration

Shock

3

Waterproofness

Dielectric withstanding

4.6 Conformance inspection.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A

inspection (see. 4.6.1.2)

4.6.1.1 Inspection lot. All switches that appear on the same MS standard or specification sheet and

that are offered for delivery at one time shall be considered a lot for purposes of sampling and inspection.

4.6.1.2 Group A inspection. Group A inspection shall consist of the inspections specified in table II.

The inspections may be performed in any order, except dielectric withstanding voltage shall be performed

after seal testing.

randomly selected group(s) of samples is required. For acceptance of the lot there shall be zero

occurrences of defects.

TABLE II. Group A inspection.

Requirement

Test method

Inspection

Sampling Plan

paragraph

paragraph

Examination of product

Material

Design construction

Calibration

Dielectric withstanding

Marking

Workmanship

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business