MIL-DTL-83731/21B

REQUIREMENTS:

Dimensions and configuration: See figures 1 and 2.

Material and finish: Bushing shall be brass, nickel plated. Toggle lever shall be brass, bright chrome

plated. Frame shall be stainless steel. The contacts shall be gold plate over nickel over silver over

brass.

Mounting hardware: Each switch shall be supplied with one hexagon nut and one internal-tooth

lockwasher in accordance with the appendix of MIL-DTL-83731, one locking ring (see figure 3), and

one

panel seal (see figure 3). The panel seal shall be silicone rubber.

Weight: .02 pound maximum.

Electrical ratings: See table I.

Strength of terminals: Method 211 of MIL-STD-202, test condition A. The applied force shall be one

pound.

Strength of toggle lever, pivot, and lever stop: Test (a) shall use a 10 pound load; test (b) shall use a 8

pound load.

Dielectric withstanding voltage: Test at atmospheric pressure only.

Mechanical endurance: 10,000 cycles at -25ºC +0ºC, -4ºC, and 10,000 cycles at 71ºC +4ºC, -0ºC.

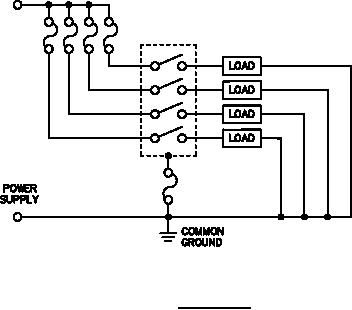

Electrical endurance, electrical overload, electronic logic, and temperature rise: Multipole switches are

to be tested with a load on each pole and with the same polarity on adjacent poles in accordance with

figure 2.

High level resistive load (dc and ac): 10,000 cycles. Altitude testing not applicable.

FIGURE 2. Test circuit.

4