MIL-DTL-3786/4M

NOTES:

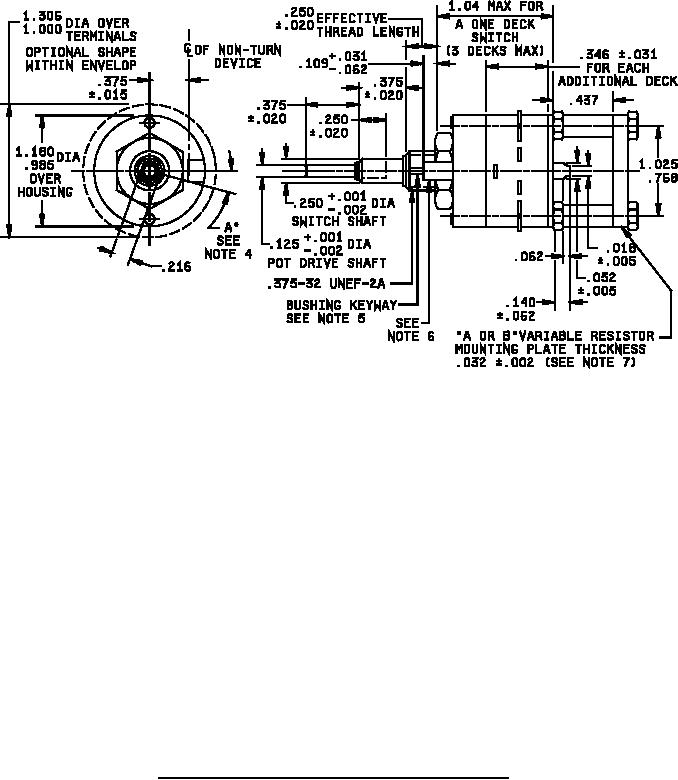

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Unless otherwise specified, tolerances are ±.005 (0.13 mm) and ±3° on angles, (nonaccumulative).

4. Shaft-flat angle A° is the angle between a line through the center of the shaft and center of the nonturn

device, and another line through the center of the shaft and the center of the nonturn device, and another line

through the center of the.250 diameter shaft and perpendicular to the shaft flat, with switch in the extreme

counterclockwise position. This refers to panel position; see figure 2 for terminal location. The .125 diameter

shaft does not have a flat.

5. Bushing keyway .069 (1.75 mm) ±.005 (0.13 mm) wide by .036 (0.91 mm) ±.003 (0.08 mm) deep measured

from a .375 (9.53 mm) diameter.

6. For sealed shaft and bushing switches, integral tab shall not be furnished. Busing keyway shall be used for

nonturn characteristic.

7. Resistor mounting plates: Two resistor mounting plates shall be made of corrosion resistant steel, and shall

be of the configuration shown on figure 1 (resistor mounting plates). These plates are designed to allow

alignment of switch position 1 with full counterclockwise stop of resistor (viewed from shaft end). Only one of

the two plates provided with switch is to be used in adapting switch to resistor.

8. Variable resistors: Variable resistors shall be in accordance with the styles covered in

MIL-PRF-94/3 and MIL-PRF-94/5 with N (standard) type bushings, and SL type operating shafts for MIL-PRF-

94/3 and SB type operating shafts for MIL-PRF-94/5.

FIGURE 1. Dimensions and configuration (style SR04-3, ADD-A-POT) - Continued.

3