MIL-DTL-13735G

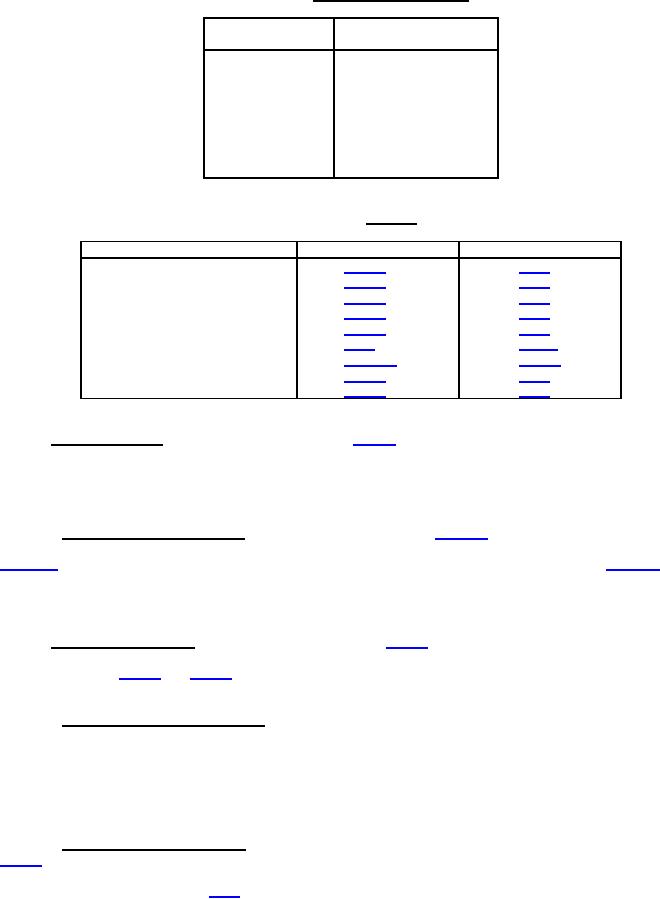

TABLE III. Zero defect sampling plan.

Minimum number of

Lot size

switches to be tested

All

1 - 12

13

13 - 150

20

151 - 280

29

281 - 500

34

501 - 1,200

42

1,201 - 3,200

50

3,201 - 10,000

60

10,001 - 35,000

TABLE IV. Group B.

Description

Requirement

Test

Contact voltage drop

Withstanding force

Average operating force

Overload

Contact voltage drop

Waterproofness (grade 1 only)

Terminal strength

High voltage

Contact voltage drop

4.8.6 Withstanding force. To determine conformance to 3.4.2.1, the switch shall be mounted as in intended

operation, to a suitable plate. With the lever in one extreme position, the specified withstanding force shall be applied

to the lever in the direction opposite to the direction of travel of the lever for 30 ± 1 seconds. This shall be repeated

four times. With the lever in the other extreme position, the same force shall be applied in the same manner, the

same number of times.

4.8.6.1 Connector or terminal strength. To determine conformance to 3.4.2.1.1, the switch shall be mounted as in

intended operation, by means of a suitable mounting plate or fixture. If the switch has connectors conforming to

MS33800, or other male-female connectors directly attached to the switch body, the force specified in 3.4.2.1.1 shall

be applied to each mating connector cable in a direction perpendicular to the connector pin. If the switch has leads,

the force shall be applied to each lead in the direction of each major axis of the switch so that it will be transmitted to

the body of the switch.

4.8.7 Average operating force. To determine conformance to 3.4.2.2, an average operating force shall be defined

as the sum of all the forces required to move the switch lever between any two given adjacent lever positions during

the test specified in 4.8 7.1 and 4.8.7.2 divided by the number of times the lever is moved between these same

adjacent positions by a force during the same test.

4.8.7.1 Switches without a center position. The switch shall be mounted, in operational condition, to a suitable

mounting plate or fixture. With the switch lever initially in a maintained contact position, a gradually increasing force

shall be applied to the switch lever in the direction of lever travel, until the lever is in the opposite position. If the

switch is class B, a gradually increasing force shall then be applied in the opposite direction until the lever is in the

original position. If the switch is class A, the lever shall then be released and the release time measured. The same

process shall be repeated four times. The average operating force and the average of the release times shall be

computed.

4.8.7.2 Switches with a center position. With the switch lever initially in center position, the procedure specified in

4.8.7.1 shall be followed treating the center position and one extreme position as an individual switch. The same

procedure shall also be followed, treating the center position and the other extreme position as an individual switch.

The average operating forces (see 4.8.7) and the average of the release times shall be computed.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business