MIL-DTL-13625F

4.3.3 Testing.

4.3.3.1 Conformance inspection. Samples selected in accordance with 4.3.1.2 shall be subjected to

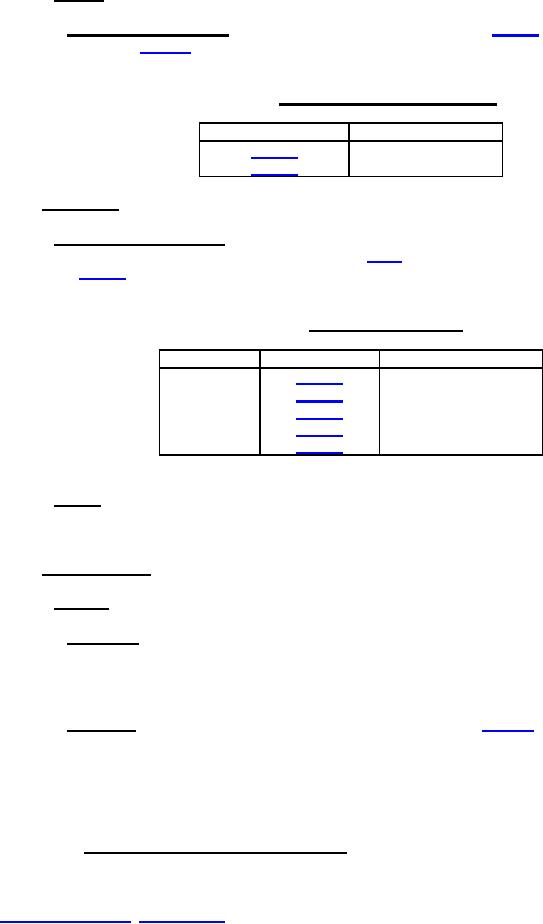

the tests specified in table IV.

TABLE IV. Order of conformance inspection.

Paragraph number

Test sequence

Terminal strength

Operating force

4.4 Control test.

4.4.1 Sampling for control tests. The control test sample shall be identified as to production period and

after having been examined for the defects specified in 4.4.2, they shall be subjected to the tests

specified in table V in the order listed.

TABLE V. Order of control testing.

Sample no.

Paragraph no.

Test sequence

Operating force

Contact voltage drop

All

Electrical overload

Waterproofness

Contact voltage drop

4.4.2 Failure. Failure of any control test sample to pass any examination or test specified herein may

be cause, at the option of the Government, for refusal to accept subsequent lots until the faults revealed

by the test have been corrected.

4.5 Test procedures.

4.5.1 General.

4.5.1.1 Conditions. Tests shall be conducted under general laboratory conditions acceptable to the

Government. Unless otherwise specified in the individual test procedures, switches shall be temperature

stabilized at 77F 15F and tests shall be conducted at an ambient of 77F 15F. However, soaking

need not be repeated where tests are continuous at that temperature.

4.5.1.2 Apparatus. In addition to standard measuring equipment (see table VI and applicable test

specifications), test apparatus shall include a testing chamber capable of maintaining specified air

temperatures over the range from -65F to +165F. Air movement in the high temperature chamber shall

be held to a minimum to prevent a temperature gradient within the chamber and any cooling resulting

from excess air motion. There shall also be a submersion tank capable of producing and maintaining a

pressure of 6 pounds per square inch (psi) and vacuum of 6 psi.

4.5.1.3 2 Test equipment and inspection facilities. Test and measuring equipment and inspection

facilities of sufficient accuracy, quality, and quantity to permit performance of the required inspection shall

be established and maintained by the contractor. The establishment and maintenance of a calibration

system to control the accuracy of the measuring and test equipment shall be in accordance with

ANSI/NCSL Z540-1, ISO 10012-1 or approved equivalent.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business