MIL-DTL-12211G

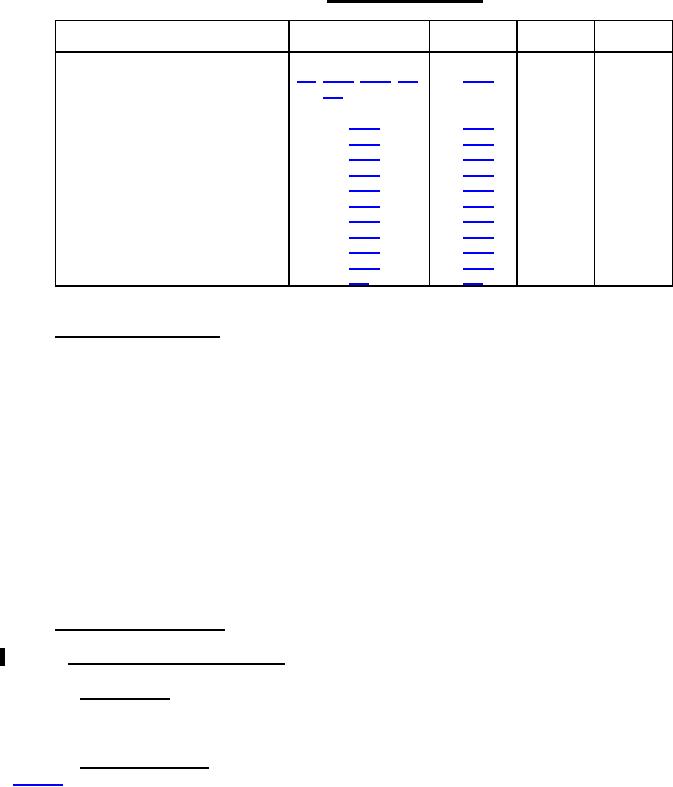

TABLE II. Qualification inspection.

Requirements

Method

Number

Number

Inspection

paragraph

paragraph

of sample

of defects

Visual and mechanical examination

and 3.9 inclusive.

Calibration

Terminal strength

Pressure overload

High voltage

4

0

Corrosion resistance

Fungus resistance

Immersion

Extreme temperature resistance

Shock

Vibration, high frequency

Endurance

4.5 Retention of qualification. Every 12 months, the manufacturer shall verify the retention of

qualification to the qualifying activity. In addition, the manufacturer shall immediately notify the qualifying

activity whenever the group B inspection results indicate failures of the qualified product to meet the

requirements of this specification. Verification shall be based on meeting the following requirements:

a. The manufacturer has not modified the design of the item.

b. The specification requirements for the item have not been amended so far as to affect the

character of the item.

c.

Lot rejection for group A inspection does not exceed the group A sampling plan.

d. The requirements for group B inspection are met.

When group B requirements were not met and the manufacturer has taken corrective action satisfactory

to the Government, group B inspection retesting shall be instituted.

4.6 Conformance inspections.

4.6.1 Inspection of product for delivery. Inspection of packaging shall consist of group A

4.6.1.1 Inspection lot. An inspection lot, as far as practicable, shall consist of all switches produced in

a period not to exceed 30 days, produced under essentially the same conditions, and offered for

inspection at one time.

4.6.1.2 Group A inspection. Group A inspection shall consist of the examination and tests specified in

table III and shall be made on the same set of sample units, in the order shown.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business