MIL-PRF-8805/39J

Fluid resistance: Except for the cut end of the lead wire, switches shall be submerged in each of the

following fluids for 2 minutes to 2 minutes 30 seconds, which shall consist of one cycle (one cycle is 10

minutes to 12 minutes 30 seconds total). Each switch shall be subjected to three cycles.

a. Turbine fuel (MIL-DTL-5624).

b. Hydraulic fluid (SAE AS1241).

c. Coolanol (MIL-PRF-87252).

d. Ethylene glycol (ASTM-E-1119).

e. Lubricating oil (MIL-PRF-7808).

After each immersion, the excess fluid shall be blown off the external surfaces of the switch with an air

jet. Following the third cycle, the switch shall be subjected to and shall meet the requirements for

dielectric withstanding voltage, insulation resistance, operating characteristics, seal tests, and marking

visibility.

Marking: The circuit schematic shall be marked on the switch case.

PIN: See table I.

Qualification inspection:

Group submission: See table III.

Group A inspection:

Seal test: Only watertight test shall be performed.

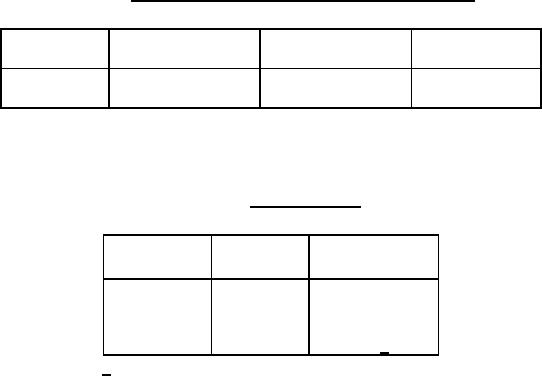

TABLE I. Part or Identifying Number (PIN) and characteristics.

A diameter

Lead wires,

PIN

B maximum

maximum

number required

MS21321-1

.720 (18.29)

.980 (24.89)

6

MS21321-2

1.031 (26.19)

1.200 (30.48)

12

NOTE: MS21321 was superseded by MIL-PRF-8805/39, the MS21321 PINs

were retained.

TABLE II. Electrical ratings.

Sea level

50,000 feet

Load

28 V dc

28 V dc

(Amperes)

(Amperes)

Resistive

7

7

Inductive

4

2.5

Motor

4

4 1/

1/ Application information only.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business