MIL-DTL-83731/16D

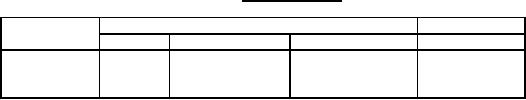

TABLE I. Electrical ratings.

High level (current in amperes)

Logic level

Type of load

28 V dc

125 V ac, 60 Hz

115 V ac, 400 Hz

5 V dc

0.010 ampere

5

5

5

Resistive

---

2

2

2

Inductive

---

1

1

1

Lamp

Resistive load (dc and ac): Switches shall make and break the rated resistive load for 10,000 operating cycles at

room ambient pressure and a temperature of 71°C +4°C -0°C.

Inductive load (dc and ac): Switches shall make and break the rated inductive load for 10,000 operating cycles at

room ambient temperature and pressure.

Lamp load: Switches shall make and break the rated lamp load for 10,000 operating cycles.

Logic level load: 10,000 cycles at an actuation rate of 10-18 cycles per minute with no "stick" or "misses" allowed

when tested in accordance with EIA RS-448-4, method 17 as follows:

Each pair of switch contacts shall be tested using a 5.0 ±0.05 V dc, 10 ± 1 mA resistive load. During each

closure of the contacts, the voltage drop across the switch terminals shall be monitored for a duration of no

less than 50 percent of each contact static closure. The switch contacts need not be monitored until 10 ms

after the initial contact closure to exclude any contact bounce. During each opening of the contacts, the

voltage drop across the switch terminals shall be monitored for a duration of no less than 50 percent of each

contact opening.

A voltage of 2.1 volts or greater across the switch terminals shall constitute a contact "miss", (failure to

properly close the circuit). A voltage drop of less than 90 percent of the open-circuit voltage shall constitute

a contact "stick" (failure to properly open the circuit).

The monitoring device shall either record the contact closures at which "sticks" or "misses" occur, or

discontinue the test when "sticks" or "misses" occur.

Operating temperature:

a.

50 percent of the test cycle at room ambient conditions.

b.

50 percent of the test cycle at 71 +4°C or -0°C.

Short circuit: Use 100 amperes at 28 V dc.

Flux sealed: The sealing is obtained when the base is sealed to prevent flux from entering the switch case during

the wave soldering process.

Flux seal test: Three switches shall be tested as follows during qualification and group B inspection: Measure

and record initial contact resistance. Place switches, terminals down, into a shallow pan. Pour flux at 80°F ±5°F,

type RMA of ANSI J-STD-004, specific gravity 0.896, into pan without splashing until level of flux is approximately

.062 inch (1.57 mm) above the bottom of the plastic switch case and let switches soak for ten minutes. Remove

switches from flux, clean with flux cleaning solvent and immediately put into oven for drying at 175°F for two

hours. After switches have cooled at room temperature, repeat initial measurement. Contact resistance shall not

increase by more than 10 milliohms over the initial reading. Disassemble and visually examine the contact area

for evidence of flux shall be cause for rejection.

3