MIL-DTL-3950J

APPENDIX A

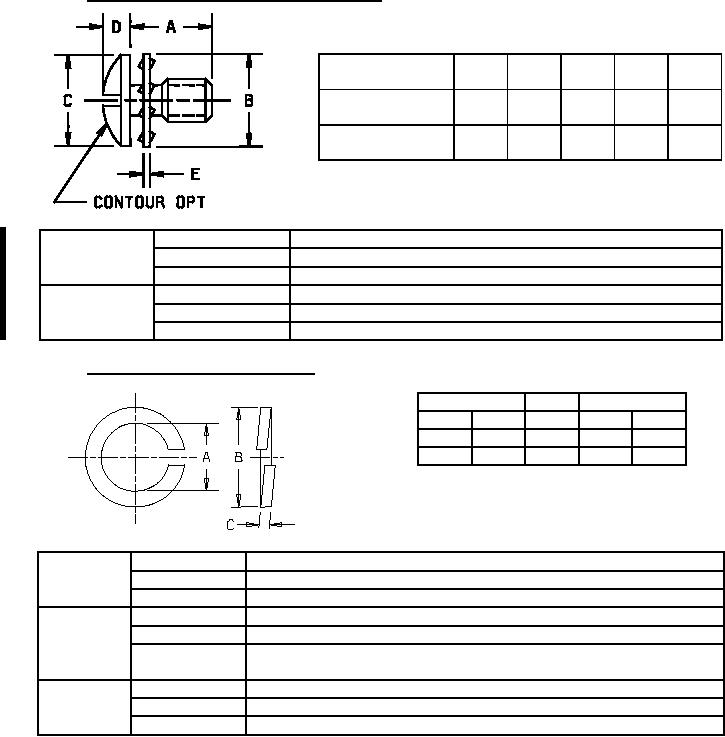

A.4.2 Screw with captive internal tooth lockwasher.

Thread

size

A

B

C

D

E

.260

.295

.290

.087

.020

.138-32 UNC-2A

.219

.265

.256

.071

.016

.250

.338

.322

.096

.022

.164-32 UNC-2A

.219

.327

.306

.085

.018

Screw

Material

ASTM B16, alloy UNS C36000 or C26000

(Brass)

Finish

Suitably protected to resist corrosion

MIL hardware

Can be replaced by MS51957-26 (Cross Recessed Head)

Lockwasher

Material

ASTM B16, alloy UNS C51000

(Phos bronze)

Finish

Suitably protected to resist corrosion

MIL hardware

NASM35333-105(.138) or NASM35333-106(.164)

A.4.3 Washer, lock-spring, helical series

A

B

C

Min

Max

Max

Min

Max

.141

.151

.253

.031

.037

.168

.178

.296

.040

.046

Material

SAE-AMS- QQ-S-700

Steel

Finish

Suitably protected to resist corrosion

MIL hardware

Can be replaced by NASM35338-41 (.138) & NASM35338-42 (.164)

Material

SAE-AMS-STD-66

Cres

Finish

Passivated

MIL hardware

Can be replaced by NASM35338-155 (.138) & NASM35338-156

(.164)

Material

ASTM B139, alloy UNS C51000

Bronze

Finish

Suitably protected to resist corrosion

MIL hardware

Can be replaced by NASM35338-98 (.138) & NASM35338-99 (.164)

NOTES:

1. Captive washers shall rotate freely on the terminal screw.

2. The terminal screws with the captive internal tooth lockwasher shall be threaded to within .024 of the lockwasher.

3. The terminal screw (pan head) shall be used in conjunction with the helical series lock-spring washer.

4. Dimensions are in inches.

5. Metric equivalents ( to the nearest .01 mm) are given for general information only and are based upon 1 inch =

25.4 mm.

32

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business